Ecological investigation of waste battery recycling: why the regular army can not do small workshops

Author: Gao Shan source: Shanghai Securities News

"About 70% of the waste batteries in China have to go through Xinxiang. No matter what you want, we can provide it, as long as the price is appropriate!" Wanghua (a pseudonym), the owner of a workshop in Muye District, Xinxiang City, Henan Province, told the reporter of Shanghai Securities News who secretly visited. According to him, during the peak period (during the rise of lithium carbonate price in 2022), there are thousands of small workshops engaged in battery disassembly in the local area, and there are still hundreds of workshops, which can provide various products in the industrial chain.

"Small workshops" refer to those small factories that do not have the qualification of recycling and dismantling. They not only do not have the environmental impact assessment certificate, but also do not have the safety production license and hazardous waste operation license. Some small factories do not even have the enterprise registration. The reporter recently learned that such small workshops not only exist in Xinxiang, Henan Province, but also in Guangzhou, Shenzhen, Dongguan, Foshan and other places in Guangdong Province. There are also a large number of small workshop battery disassembly plants.

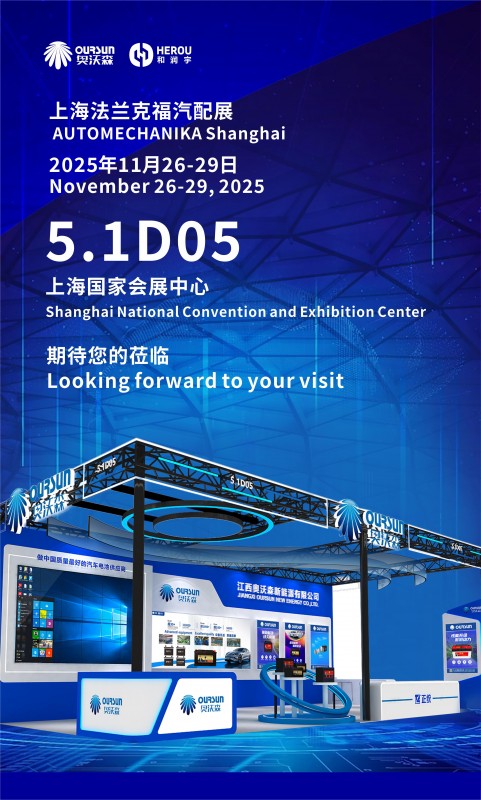

Black powder stacked in the warehouse of the small workshop

In recent years, China's lithium battery industry has made rapid progress. As a key link of green recycling, the savage growth of the battery recycling industry is a headache for all parties in the industrial chain. "Most of the scrapped batteries flow to small workshops and the echelon utilization market in the blind area of regulation. It is basically difficult for regular recycling enterprises to receive scrapped batteries, and a large number of high-quality recycling capacity are idle." Zeng Yuqun, chairman of Ningde times, said earlier.

The reporter found that compared with the regular army, small workshops have "competitive advantages" such as low cost, close combat and low threshold, but there are many hidden dangers such as environmental protection and safety, which lead to the abnormal ecology of "bad money driving out good money" in the field of waste battery recycling for a long time and need to be reshaped.

Industry insiders believe that with the recent sharp fluctuations in the price of lithium carbonate, the ecology of the waste battery recycling industry is undergoing dramatic changes. We should seize this "window period" to accelerate remediation and promote the sustainable and healthy development of the industry.

Secret small workshop "black powder" business

Where have all the used batteries gone?

"Within 10 kilometers around Xinqi street and Weiqi Road, Muye District, Xinxiang City, Henan Province, there are a large number of small workshop style 'black powder' manufacturing enterprises in many villages." at the end of March this year, after many days of searching, the reporter suddenly received a text message. There was no more information, and the caller did not answer the call back. The person who provided the clues seemed very cautious.

Starting from Zhengzhou, it is about an hour's drive to Muye District, Xinxiang City. On the rural roads, the rape flowers on the roadside are in full bloom, and there are occasional electric vehicles or tricycles passing by, which makes outsiders and foreign vehicles particularly eye-catching.

With the excuse of buying "black powder" (the black powder containing nickel, cobalt, manganese, copper, aluminum, lithium and other metals and carbon powder obtained from the process of dismantling, crushing, screening, pyrolysis and sorting of waste lithium-ion batteries), the reporter, as a trader, knocked on the door of a villager at random. As soon as he explained his intention, the other party immediately pointed out the path for the reporter -- a blue greenhouse hundreds of meters away, where there was a small factory.

Seen from the roadside, this small workshop is covered with an ordinary large tin shed with a wide gate or for the convenience of vehicles. But it is difficult for outsiders to see that this is a small factory unless someone gives directions. A small door was left on the gate of the factory. When I knocked on the door, I saw several discarded battery packs scattered in the hall.

"I don't powder. Now the price of lithium carbonate is falling every day. It's hard to do business in this market." Mr. Luo, the boss, is very cautious. He told reporters that he was mainly engaged in the secondary utilization of batteries.

Under the introduction of Luocheng (a pseudonym), the owner of another small workshop, the reporter met Wang Hua, a boss who "has done a lot of battery business" in Xinxiang. Enter through a small door facing the street, go through an alley, open an iron door, go through a yard, and open a door, which is Wanghua's warehouse. The reporter saw that dozens of large woven bags were stacked in the warehouse, which contained "black powder".

According to Wang Hua, he also has a milling factory, which has not been started recently and does not have a lot of inventory on hand. If needed, he can quickly help organize the supply of goods.

The reporter found that the vast majority of small workshops were not listed and had strong concealment. Very few enterprises have the brand of "XX battery raw material factory". The bosses will declare in advance that "no invoice can be issued" before the transaction.

Multiple risks exist in disassembly and reuse

"Are you afraid of accidents when you powder here? What if the battery explodes?" leaving Wang Hua's warehouse, the reporter and Luo Cheng continued chatting all the way.

"Just be careful. There were also accidents. A factory was blown up before, but the people were all right. The battery in a warehouse was gone." Luo Cheng said.

Lithium battery pack itself has high energy, which may cause various safety problems such as short circuit and liquid leakage, and then may cause fire or explosion. The reporter learned from an unannounced interview that the production environment and equipment of the small workshops are relatively simple, and the operation is often not standardized. There are safety risks such as explosion and fire when disassembling the battery.

Not only disassembly, lithium batteries themselves are dangerous goods, and storage and transportation are also faced with greater risks. The resulting fire accidents are not uncommon. More worrying is environmental pollution. For example, improper disassembly of waste lithium-ion batteries may cause heavy metal ion pollution such as nickel, cobalt and manganese, fluorine pollution and organic pollution.

"We mainly do the first half of (disassembly), not wet (chemical decomposition), and the environmental protection problem is fairly good." Luo Cheng was unwilling to talk about this topic more. Another small workshop owner in Xinxiang also said that the local government was not too strict in this area.

Waste of resources is also a major problem. Some of the materials that can be recycled by the formal recycling and dismantling enterprises can only be treated as garbage in small workshops, which is not conducive to recycling.

However, Luo Cheng insisted that he and his peers have sold all kinds of materials after classifying them, and have made the best use of resources. Wang Hua revealed to reporters that "black powder" was mainly sold to several well-known domestic recycling enterprises, such as a leading enterprise in Jiangxi, and had a deeper cooperation with him at one time.

This is consistent with what the reporter learned. It is understood that small workshops cannot complete the whole recycling process, mainly for pretreatment, and the extracted materials are mainly used by formal enterprises.

Compared with safety, environmental protection and other risks, another risk may directly damage the interests of consumers.

In September 2022, the police in Zhangjiakou, Hebei Province, disclosed a case of selling goods with counterfeit registered trademarks. The local police seized more than 150000 counterfeit "Nanfu" batteries at the scene of the destroyed battery manufacturing dens, involving a value of more than 500000 yuan. According to the investigation, the dens for making fake batteries are located in Xinxiang, Henan Province. One dens for making fake batteries and one warehouse for storing fake batteries were removed in Xinxiang, and seven suspects for manufacturing and selling fake "Nanfu" batteries were successively arrested.

It is understood that the so-called secondary utilization in some small workshops is to take apart the battery pack, select or simply test it according to the shape, and then replace a package and sell it. The downstream includes children's toy manufacturers, small appliance manufacturers, etc., such as the battery in some hand-held electric fans, which is often used in echelons.

"We have all kinds of batteries you need," Luo Cheng told reporters before leaving.

"The higher the price," the regular army can not do small workshops

Xinxiang, why can there be so many small workshops for battery disassembly? How do they get used batteries?

"The main thing is the price. If you pay a high price, others will sell it to you." according to a local person who is engaged in the dismantling of waste batteries, after years of development, some small bosses in Xinxiang have established some recycling channels, and they are "in a group" and have an advantage in seizing supply. He said, for example, that the boss of a Xinxiang found a batch of goods, which might cost tens of millions of yuan. It was very difficult for one person to get it, and we could quickly finalize it.

In fact, the battery industry in Xinxiang has a long history. In 1950, the first battery enterprise in Henan Province was established in Xinxiang. In 1956, the state-owned 755 factory, the first secondary battery production enterprise in China, was also built in Xinxiang. It is one of the most complete battery production bases in China. It was once one of the top ten battery export bases in China and is known as the "Whampoa Military Academy in China's power industry".

"His grandfather is a battery maker, and his father is also a battery maker. In his generation, he has to rely on batteries." during the chat, a local villager introduced his partner.

It is also the recycling, dismantling and reuse of waste batteries. What is the reason for a regular enterprise but a small workshop?

"From the recycling side, we really don't have them to dare to bid." the relevant person in charge of a white list dismantling enterprise in South China told reporters that compared with regular enterprises, small workshops have almost no investment in environmental protection and do not need to pay taxes, and family workshops have also significantly reduced human costs.

It is understood that due to the lack of a unified standard for lithium batteries, the battery pack structures of different manufacturers and different models are different. Although a number of leading enterprises have made technological breakthroughs in intelligent disassembly, their comprehensive advantages are not obvious, and manual disassembly is still the main operation mode.

At the same time, the small workshops have little investment in environmental protection, and the investment in fixed assets, production costs and other aspects are very low. This has also led to the proliferation of small workshops. Some small workshops even buy a crusher at home and complete the processing in their own yard.

The dismantling of waste batteries is not only gathering in Xinxiang, Henan Province. The reporter learned from the interview that there are also a large number of "workshop type" battery disassembly plants in Guangzhou, Shenzhen, Dongguan, Foshan and other places in Guangdong.

According to the statistics of energy storage application branch of China chemical and physical power industry association, at present, less than 25% of the retired batteries flowing to the white list enterprises, and 75% of the business is digested by "small workshops" and enterprises that have not yet entered the white list. In addition, according to the statistics of Gaogong lithium battery, only 20% to 30% of the retired power batteries are recycled through formal channels.

"Eliminate the good and retain the bad"

Ecology needs to be changed

The ecology of "bad money drives out good money" needs to be changed. During the two sessions of the National People's Congress this year, how to rectify the chaos of the battery recycling industry has become the focus of the new energy industry.

Liujingyu, chairman of China Innovation airlines, suggested that the top-level planning of the battery recycling system should be carried out, and the power battery enterprise should take the lead to formulate the battery recycling route from the source of product design and establish an efficient battery recycling system; Formulate standards and specifications for the recycling process to ensure that the recycling is low-carbon, environmentally friendly, efficient and has economic value; Give priority to supporting power battery enterprises with the ability of big data management in the whole life cycle of power batteries and mastering the recycling technology of low energy consumption and zero pollution materials for industrial layout.

Liuchanglai, chairman of camel Co., Ltd., found that the current recycling channels of power batteries in China are not standardized, and a large number of retired power batteries have flowed to informal recycling channels in the form of "the higher the price", resulting in distortions such as the unsaturated operation of the production capacity of formal enterprises and the "bad money drives out good money" in market competition.

Zhangtianren, chairman of Tianneng holdings, mentioned that the current competition pattern in the domestic power battery recycling industry is still "small, scattered and disorderly". There are problems in the development of the industry, such as the difficulty in managing the flow of batteries, the confusion of battery recycling prices, and the disorderly expansion of unqualified small workshops.

One background of the collective appeal of the leaders of leading enterprises in the battery industry chain is that China has ushered in the peak of the first batch of power battery retirement. According to the calculation of the average service life of power batteries from 5 to 6 years, the first batch of power batteries for commercial new energy vehicles have been decommissioned in recent two years. The theoretical recovery of decommissioned power batteries is expected to exceed 300000 tons in 2023, and it is expected to reach 500000 tons in 2025. According to the 2022 China lithium battery industry development index, the number of retired power batteries has increased significantly since 2021, with a total of 34.5gwh (277000 tons) in 2022. It is expected that the number of retired power batteries will reach one million tons per year after 2025.

Government departments have also been continuously promoting standardized recycling. At the press conference on the theme of "the opening of the authoritative departments" held by the State Council Information Office on March 1, xinguobin, Vice Minister of the Ministry of industry and information technology, proposed to improve the recycling system, strengthen the research on key technologies such as intelligent disassembly, and improve the recycling level of power batteries.

Reproduced in http://www.batterychn.com/newinfo-1013-2